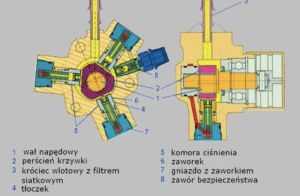

High pressure pump

High pressure fuel pump

A frequent case of pump damage is also a breakage of the discharge section valve spring. In the case of damage to one section, the engine starts and you can drive, but there is a problem when the engine is loaded when the computer wants to increase the pressure in the rail to 90 bar.

There is also frequent squeaking near the pump indicating intense friction of the pumping section sliders. In such a case, mixol should be immediately added to the fuel in a proportion of 1: 100. Driving with a squeaking pump will wear it down quickly.

High pressure pumps can also be regenerated. The cost of regeneration depends on the degree of damage, but if the pump is worn out, regeneration is not profitable. In order to extend the life of the pump, it is recommended to periodically add cleaning agents to the fuel and to add a small amount of Mixol (1: 200-300) to each refueling.

The pump performance can be checked under road conditions. In 3rd gear, at approx. 1500 rpm, depress the accelerator pedal as far as it will go. The engine should pull evenly up to 6,500 rpm. If, around 3500 rpm, there is a noticeable drop in power, jerking or switching on the emergency mode, it means that the high pressure pump has probably reduced efficiency.

Dissasembly and assembly of the pump

Very important ! The high pressure pump may only be removed when the engine is cold. You should also have a fire extinguisher nearby, just in case. Attempting to remove it while the engine is hot may result in fire. The fuel is under high pressure and temperature of approx. 100 ° C. Unsealing of such a system leads to the immediate boiling of gasoline and its discharge outside, which may cause ignition and explosion of vapors or burns.

Remove the quick coupler of the fuel supply line and unscrew the steel conduit connecting the pump with the rail with a wrench [17]. It is best to hold the spigot protruding from the pump with the key [15], because usually it starts to unscrew first and the fuel line is twisted. Then unscrew the three screws [10] securing the pump to the head body. The pump should slightly pop out of the head. There is a reduction in the tip of the injection rail, which can also be unscrewed. Below it is a fuel filter mesh. Carefully check if there is any black deposit on it or, in extreme cases, even chips. This deposit indicates wear of the section piston sliding shoes and most likely the pump should be regenerated or replaced.

Demage to the pump

Damage to the high pressure pump can be divided into two reasons: the first is natural mechanical wear, it occurs after 180-200 thousand km. As a result of friction of the piston guides, they irreversibly lose their tightness and the pump loses its parameters, not reaching the appropriate pressure. Wear is also often evident in the form of black sludge or even chips in the filter at the entrance to the injection rail. In the event of wear, the pump must be replaced with a functional one. The durability of the pump depends on the purity of the fuel and ranges from 180,000 km to almost 250,000 km when the car was running on Western fuel. In our conditions, it is recommended in the Lagoon to install an additional filter on the fuel line when the existing mesh filters do not ensure the proper purity of the fuel.

The second case is damage to the pumping section. It consists in a breakage of one of the valve springs. The pump with a damaged lower valve has a reduced efficiency, which is manifested in jerking or switching to emergency mode when the engine is heavily loaded, e.g. during acceleration. If the upper valve is damaged, the pump cannot build up pressure and the engine is virtually impossible to operate. In this case, the pump can be repaired by replacing the damaged section with a functioning one. In the event of damage to two sections, the repair depends on the state of wear and at the current prices of new pumps is practically unprofitable.

The connector of the injection rail after removing the mesh filter

F5R pump

F5R high pressure pumps are now available for idE engines. These are replacements for original Renault pumps that are no longer available on the market.