Fuel pressure sensor

Fuel pressure sensor

The pressure sensor is designed to provide the engine computer with data about the current pressure in the injection rail. The correct operation of the sensor is essential for the correct operation of the engine.

The sensor is one of the most unreliable elements of the fuel system and it is better not to touch it unnecessarily. The sensor is powered by 5V and depending on the pressure, the output voltage varies from 0.5 to 3.2V. The voltage of 0.5V occurs in the absence of pressure or at very low pressure (5bar from the forepump). As the pressure increases, the voltage increases and at about 3.5V the pressure is critical for an engine of 120bar. In conditions of proper operation, it should not drop below 2.2V and exceed up to 3V depending on the engine speed and load, which corresponds to a pressure of 60-90bar. After warming up at idle, it is about 2.6V, the voltage may also be lower and it depends on the engine software version. The models from the first years of production had a lower idle pressure and then the subsequent versions got higher and higher.

The method is quite indicative, but allows for an initial diagnosis without the use of a computer. The pressure sensor number is 7700113205.

In the event of damage to the engine pressure sensor, it usually cannot be started (Megane) or it can be started (Laguna), but immediately enters emergency mode with a limiter to 3000 rpm. and [injection fault] appears. When the sensor is damaged, the computer usually displays a pressure of approx. 170 bar. Do not remove the plug from the sensor and regulator with the engine running, as this may block the active pressure regulation function

Dissasembly and assembly of the sensor

Very important ! The pressure sensor may only be removed when the engine is cold. You should also have a fire extinguisher nearby, just in case. Attempting to remove it while the engine is hot may result in fire. The fuel is under high pressure and temperature of approx. 100 ° C. Unsealing of such a system leads to the immediate boiling of gasoline and its discharge outside, which may cause ignition and explosion of vapors or burns.

Use the socket wrench [27] to unscrew the sensor. In the absence of such a key, remove the regulator and unscrew the sensor with a flat wrench. Despite the large diameter of the key, the valve is screwed on with a relatively low torque, because it has a fine thread and is screwed into the aluminum strip. The sensor should not be unscrewed unnecessarily, as it is easy to break the thread in the strip.

You absolutely must not unscrew the sensor by grasping the plastic socket, it is very easy to break it or twist it in relation to the housing, then the delicate connecting tape is broken.

Sensor structure

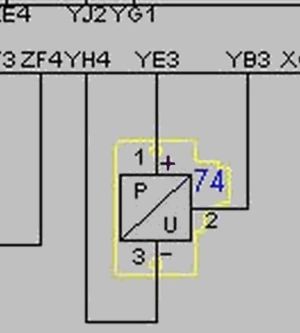

The interior of the pressure sensor, the piezoelectric sensor is located under the electronics board

The sensor is protected by the MLX12106E circuit and therefore resistant to short-circuit of leads, connection of voltage higher than 5V (max 14V) and change of polarity. Thanks to this design, the system is practically failure-free. Working range from -40C to 150C

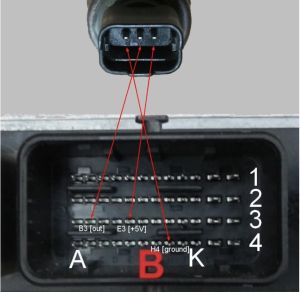

Electrical connection

Diagram of connection of the pressure sensor to the Sirius 35 computer (Laguna II). The Y marking is the middle socket of the computer.

In the event of an incorrect pressure reading (over 170 bar or below zero), it is necessary to check the correct connection of the sensor to the computer.

F5R Team sensor

F5R Team pressure sensor. It is an inductive sensor with incomparably greater durability and reliability than the original piezoelectric sensors. Sensor designation UE116120PL.